Tea Testing Lab Service

Tea contains catechins, folic acid, pantothenic acid, caffeine, inositol and other ingredients to enhance human health. Tea is known as "one of the world's three major beverages." In order to maintain the credibility of tea, to promote the prosperity of the tea market, and to protect the interests of consumers, the International Standardization Organization-Agricultural Food Technology Committee Tea Subcommittee recommended international standards and testing methods for tea.

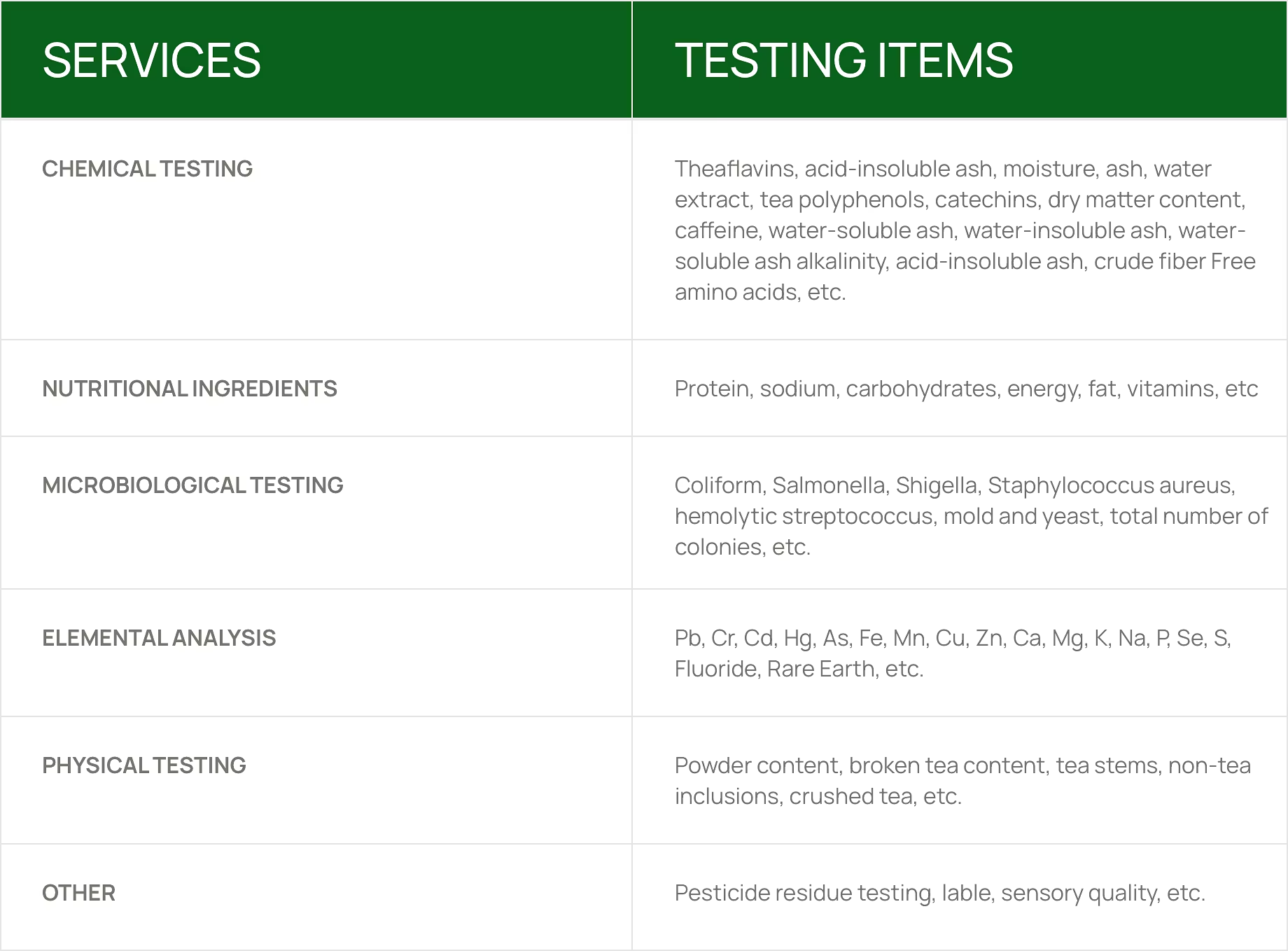

Sannidhi Tea offers a wide array of capabilities and testing services for the tea industry. From authenticity testing to microbiological testing, Sannidhi Tea provides incredible service and credible results. Sannidhi Tea is your one-stop laboratory for all tea analysis.

Tea types that SANNIDHI TEA can test:

CTC TEA METHOD

WITHERING

Fresh, green tea leaves are withered to reduce the moisture content and allow the flavour compounds to develop. Freshly plucked leaves are laid out in a series of troughs and subjected to carefully monitored and conditioned air.

CTC OR CRUSH, TEAR AND CURL PROCESS

This process involves shaping the withered leaves into a tight form. Stainless Steel Mandrels, where grooves are intricately ground, lend the shape and granular nature to the tea. During the process, essential oils and sap tend to ooze out of the leaves, intensifying the taste further.

FERMENTATION

Here, the enzymatic browning of the processed leaves is controlled through the application of air.

DRYING

To give the tea its natural black appearance and improve its keeping quality, moisture is rapidly evaporated from the fermented leaf. This process enhances the flavour and ensures higher shelf-life by bringing down the tea’s moisture content.

ORTHODOX TEA METHOD

PLUCKING

The leaves are harvested by hand, usually ranging between just the unopened bud to the top three leaves and a bud.

WITHERING

The leaves are laid out to gradually lose moisture and wither for several hours to prepare them for further processing. The leaves are then very gently fluffed, rotated and monitored to ensure even exposure to the air.

ROLLING

Using mechanical jackets, the withered leaves are gently twisted to give them their unique long leaved appearance.

FERMENTATION

After rolling, the leaves are laid out to rest for several minutes to allow fermentation to take place. Here, the oxygen in the air interacts with the now-exposed enzymes in the leaf, turning it a reddish-brown colour and changing the chemical composition. This step is important as it has the greatest impact on the complexity of the flavour and aroma.

FIRING

This is final step in the production process. The tea is "fired" or dried to quickly dry the leaves to below 3% moisture content and stop the oxidation process, following which the tea is graded.